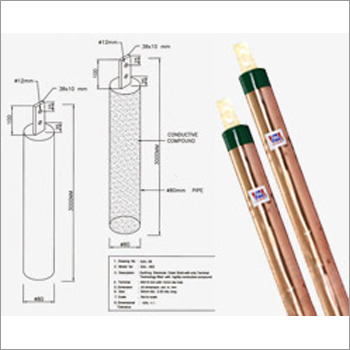

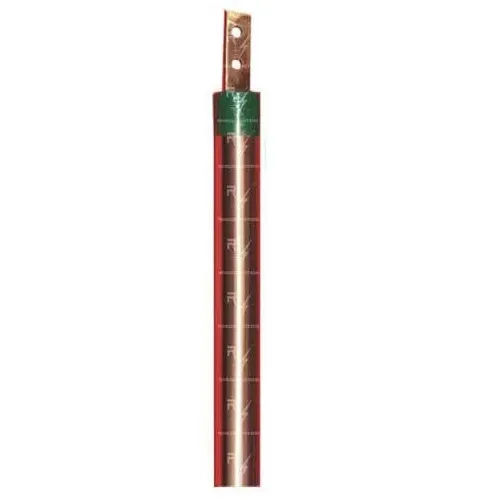

Chemical Earthing Electrodes

1900.00 INR/Piece

Product Details:

- Product Type Chemical Electrodes

- Material Copper Bonded Steel

- Application It is applied at homes, office, solar power plant, etc.

- Function To provide low resistance path in ground to any fault and leakage currents as well as to ensure smooth flow of the ground dissipation.

- Shape Round

- Surface Treating Copper Coating

- Color Copper

- Click to view more

X

Chemical Earthing Electrodes Price And Quantity

- 10 Piece

- 1900.00 INR/Piece

Chemical Earthing Electrodes Product Specifications

- To provide low resistance path in ground to any fault and leakage currents as well as to ensure smooth flow of the ground dissipation.

- Copper Coating

- Copper Bonded Steel

- It is applied at homes, office, solar power plant, etc.

- Round

- Chemical Electrodes

- Copper

Chemical Earthing Electrodes Trade Information

- 40 Piece Per Day

- 3-4 Days

- Yes

- Free samples are available

- Bundle

- All India

Product Description

Chemical earthing electrodes are used in grounding systems to dissipate electrical currents safely into the ground. They are an integral part of electrical installations, providing a low-resistance path for fault currents to flow into the earth, thereby preventing damage to electrical equipment and ensuring safety for personnel.

Chemical Earthing Electrode Features:

1. Wear and tear resistance

2. Dimensionally accurate

3. Corrosion resistance

Chemical Earthing Electrode Specifications:

1. Surface: Copper Coating

2. Length of Rod: 2000 mm

3. Electrode Type: Anode, Cathode

4. Material: Galvanized Iron (GI)

5. Brand: Zaral

6. Color: Bronze

Advantages of chemical earthing electrodes:

1. Low resistance: They provide a low-resistance path for fault currents, ensuring effective grounding.

2. Longevity: Properly installed electrodes can maintain low resistance values over an extended period.

3. Versatility: They can be used in various soil conditions and environmental settings.

4. Minimal maintenance: Chemical earthing electrodes typically require minimal maintenance compared to other grounding methods.

Chemical Earthing Electrode FAQ:

Q. How does a chemical earthing electrode work?

Ans: When installed in the ground, the chemical compounds surrounding the electrode react with moisture in the soil, forming a conductive electrolyte. This electrolyte reduces soil resistivity around the electrode, allowing fault currents to dissipate safely into the earth.

Q. How are chemical earthing electrodes installed?

Ans: Chemical earthing electrodes are installed vertically into the ground to a depth determined by soil conditions and installation requirements. The surrounding soil is then backfilled and compacted around the electrode to ensure good contact and conductivity.

Q. Do chemical earthing electrodes require maintenance?

Ans: While chemical earthing electrodes generally require minimal maintenance, periodic testing and inspection are recommended to ensure continued effectiveness. Testing methods such as soil resistivity measurements and ground impedance testing can assess the performance of the grounding system.

Q. Are chemical earthing electrodes suitable for all applications?

Ans: These are suitable for a wide range of applications, including residential, commercial, and industrial settings. However, specific requirements may vary depending on factors such as soil conditions, environmental factors, and the magnitude of fault currents.

Q. Can chemical earthing electrodes be reused if relocated?

Ans: In many cases, these products can be reused if they are carefully removed and reinstalled in a new location. However, proper care must be taken during removal and reinstallment to ensure the integrity of the electrode and the surrounding soil.

Q. What are the typical dimensions and materials used in chemical earthing electrodes?

Ans: Chemical earthing electrodes are typically made of galvanized iron or copper rods with diameters ranging from several millimeters to several centimeters, depending on the application. The surrounding conductive compound mixture may include graphite, bentonite clay, sodium chloride, and other additives.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email